|  |  |  |

| Abrasives | tool | tool | 劳保用品 |

| Abrasive tools / tape / oilstone / oil, etc | Pliers / screwdriver / power tools, etc | Turning tool / milling cutter / cutter head, etc | 安全帽/防护服/手套/鞋等 |

At present, all models have been debugged for a wide range of applications. It covers the requirements for the use of various materials in workshop production, including but not limited to abrasives / tools / cutting tools / labor protection supplies, etc.

二、系统结构

The process of the system is clearly introduced, and employees do not need to have any connection with the warehouse / warehouse keeper. Just complete the operation of the equipment, and all information is transmitted to the administrator through the equipment background. The administrator only needs to be responsible for statistical reports, making purchase plans and equipment replenishment on a regular basis.

Collecting process

This product is easy to operate. Workers only need to swipe their cards to confirm their identity, select materials and pick up goods to complete the picking up process. Compared with similar products, it simplifies the operation steps and greatly reduces the misoperation rate.

Return process

Two return modes can be selected:

1. Put the cutter into the packaging plastic box, generate the label bar code, paste it on the packaging, record the return information, and put it into the unified return port.

2. Each returnee shall be equipped with a separate grid, put the tools in their own cell, and the administrator shall count them uniformly.

Reduce the frequent printing of labels and manual counting and tearing of labels, saving time and effort.

Set receiving permission

By Department Set corresponding material receiving restrictions for different departments. |  | By function Set the corresponding material receiving restrictions for different types of work / functions / levels. |

By time According to the statistics of material usage loss in previous periods, set the material receiving limit in a fixed period. Notify if the warning line is exceeded. | By project Set project limits according to the usage of materials required by the project statistics. (employees need to choose the purpose when picking) | |

In order to facilitate the enterprise to control the cost, the function of setting the employee's permission to receive materials can be added in the background. If some functions are limited by item, you need to add and select item options on the client. | ||

3、 Equipment function parameters

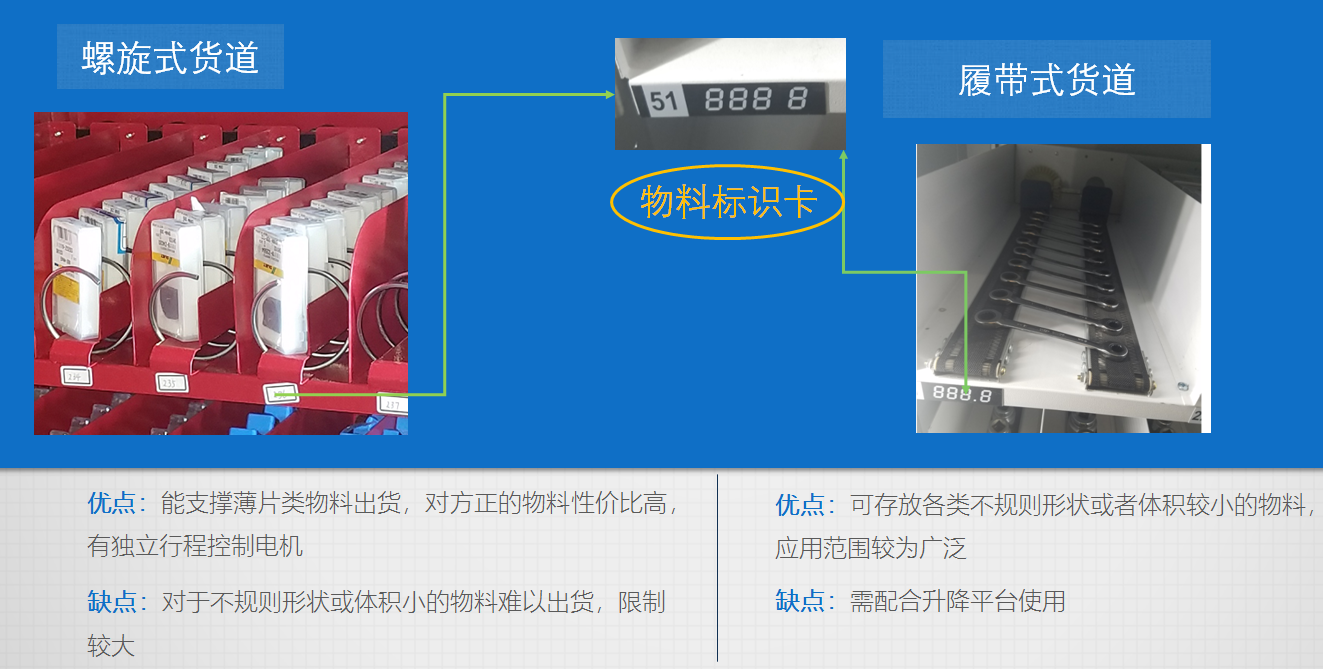

Cargo Lane classification

Cargo way type

Specific parameters

The material machine can store more than 60 different kinds of goods

The lifting platform receives goods safely and stably

Support spring shipment / crawler shipment / Spring + crawler combination shipment and other schemes

General parameters :

Length, width and height: 1955mm * 1280mm * 800mm (customizable)

Control system: win8

Voltage: 220V

Storage type: 30 ~ 80 different commodities

Storage quantity: 300 ~ 1600

Equipment characteristics :

32 inch touch screen operation for goods selection;

Card reader swiping / fingerprint identification to confirm identity;

Lifting platform grating detection and goods transfer;

Leakage protection, automatic start and automatic shutdown when calling;

Large area explosion-proof glass, LED lighting;

The fuselage is made of all steel structure, which is firm and durable

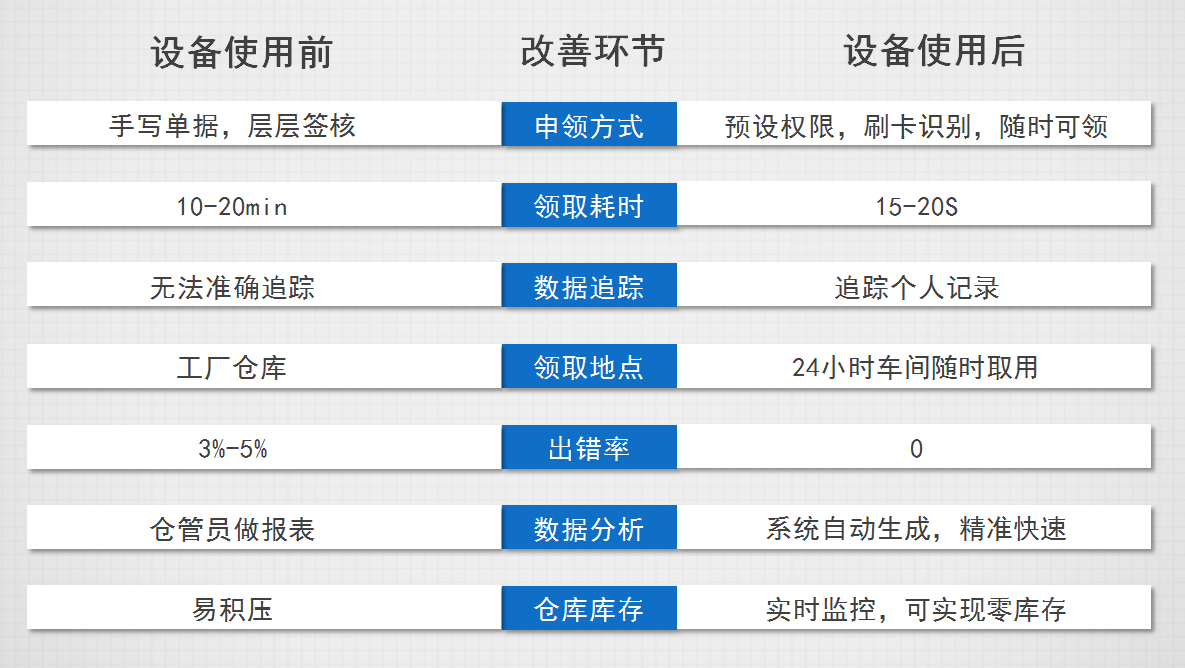

4、 Effect comparison

|

15050151202 Free service hotline |

|

Follow us Please scan the official account |

Copyright © HRC Automation(Suzhou)Co.,Ltd 备案号:苏ICP备19026496号