一、 System introduction

The intelligent measuring tool management system developed by Suzhou hangruicheng is customized according to the measuring tool management process, combined with workers' card swiping, code scanning, QR code label and other methods to realize rapid collection and return, automatically generate collection and return records, and update real-time inventory and reports.

The measuring tool management system solves the core pain points of frequent handwritten registration forms, which are easy to make mistakes, difficult to execute and difficult to count. It solves the problems of Excel management, which is difficult to efficiently manage the calibration of measuring tools, calibration files, warehousing records, statistical reports and other problems. It is customized according to the use process of measuring tools. After deployment, many well-known enterprises are very satisfied with the system function and management improvement effect.

1.1 CS function end function description

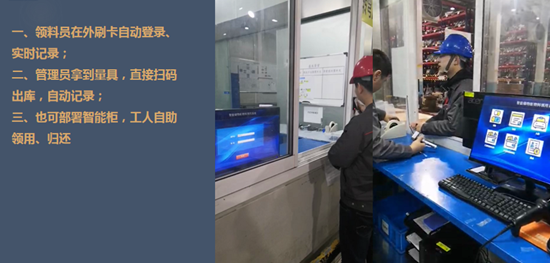

1. In order to facilitate the direct use of measuring tools and the convenient, accurate and rapid operation of management personnel, the operations of measuring tools such as receiving, returning, checking, warehousing, inventory counting and warehousing are operated at the CS end of the computer. The CS end interface needs to swipe the card to log in, so as to quickly and accurately identify the operator.

2. The measuring tool room is equipped with double screens, which are displayed inside and outside at the same time. After swiping the card, the employees can see the operation of the receiving and returning interface in real time to prevent errors and jointly confirm.

3. The number of CS terminals is not limited, and the green installation free package can be delivered to the user. After the hardware required by the contract is complete, if users expand in the future, they can configure code scanning gun and card reader by themselves.

1.2 function description of BS website

1. In order to facilitate managers or personnel of other departments to view data reports, background settings, etc., relevant modules are on the BS side of the web page. According to the assigned account and password, the corresponding personnel can access and view by entering the server address in the web browser.

2. The server can be the server provided by your company, or the configured computer can be selected as the server. The special server is more stable and reliable.

3. There is no limit to the number of accounts, which can be accessed and viewed in the LAN.

Advantages of separate design of CS and BS ends

1. The CS end is convenient for the production personnel to swipe the card for quick collection and return, the measuring tool management personnel to quickly carry out daily maintenance, check in and out of the warehouse, and the office personnel to assign an account number to view the corresponding data and reports, but they cannot operate or change the measuring tool status at will;

2. CS has strong interactivity and fast response speed. It is especially suitable for processing large quantities of data. Strong security, generally used in LAN; BS has relatively weak interactivity, relatively slow response speed and relatively low security. It is generally used in Wan and can realize cross platform and zero maintenance of clients. Therefore, some units apply BS in daily office and use CS structure in actual production.

1、 System setting module

2.1 personnel, Department, role and authority

1. View and operation permission division function

2. Dedicated line function

3. Quick recognition by swiping card or face

2.2 warehouse location, point location and intelligent cabinet

1. Digitization of all locations

2. Intelligent cabinet of common tools

3. Data management hierarchy

3、 Measuring tool information management module

3.1 basic information management of measuring tools

1. Standardization of basic information

2. Image upload visualization

3. Template of special verification index

3.2 machine tool, production line, work order and product management

1. Tracing the history of measuring tools, inspecting work orders and products

2. Tracing work orders and measuring tools used for products

3.3 management of major and minor categories

1. User-defined classification

3.4 label and certificate management

1. Optional QR code number is automatically generated

2. Automatic label printing and cutting

3. Label content customization

4. Special waterproof, oil and falling proof label

5. Label style

4、 Warehousing management module

1. Batch import function

2. Verification cycle and reminder management function

3. Verification index management function

4. Collection times management function

5. Long collecting time function

6. Department division function

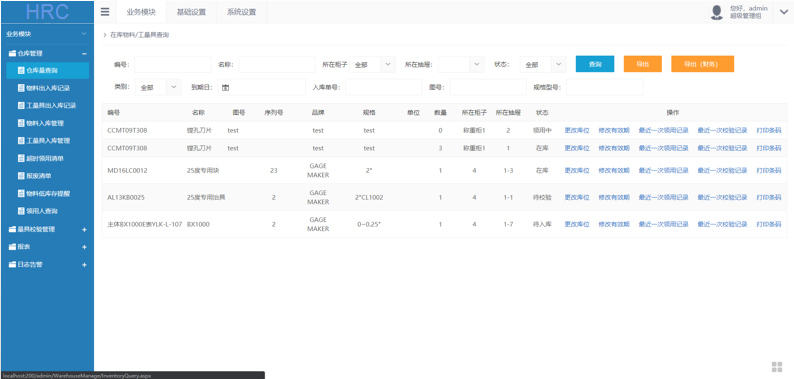

5、 Inventory account management module

1. Multi dimensional query by status, number and location

2. Status management: to be warehoused, available for collection in stock, abnormal to be verified, verified delivery, being verified, scrapped, sealed, long-term collection, etc

3. Quick tracing function: compare the last collection record and verification record

4. Location management function

5. Supplementary labeling function

6、 Collecting module

1. Automatic recording of card swiping or face swiping

2. Code scanning and quick picking out

3. Multiple query and filtering functions

3. Optional associated machine tool and production line functions

4. Optional work order and product collection functions

5. Dedicated audit function

6. Expired, overdue and abnormal automatic limit collection function

7. Automatic limit of picking out when the number of times exceeds the standard

7、 Return module

1. Quick code scanning return function

2. Abnormal, damaged and out of standard optional function to be verified

3. Others to be returned function

4. Overdue reminder function

5. You can enter the number to return the function sheet.

8、 Verification management module

8.1 abnormal to be verified management module

1. Missed inspection, overdue non inspection and abnormal automatic locking

2. Automatic locking exception for exceeding the collection times

3. Abnormal automatic locking when the index exceeds the standard

4. Automatically remind the administrator of exceptions to be verified

5. Automatically return to normal after verification

8.2 regular calibration management module

1. Automatic generation of list to be verified

2. Batch filtering by time

8.3 verify stock in and stock out

1. Code scanning and quick delivery function

2. Quick code scanning return function

3. Inspection amount, time and manufacturer record statistics function

8.4 verification document management

1. Support verification report file upload and archive management

2. Automatic photo upload function

3. Automatic report generation function of verification data

4. Verification document review process

9、 Scrapping and sealing of measuring tools

1. Special personnel have authority to audit

2. Scrap reason setting and statistics function

3. Measuring tool sealing management function

10、 Measuring tool inventory function

1. Support screening by region and variety

2. Convenient indication function of warehouse location and photos

11、 Report module

1. Stock in and stock out history

2. Scrap statistics

3. Reminder table not yet

4. Inventory status list

5. Reminder form to be verified

6. Abnormal to be verified reminder table

7. Purchase cost statistics

8. Verification cost statistics

9. Personnel collection query table

10. Statistical table of calibration records

11. Statistical table of measuring tool indicators

12、 Hardware configuration

1. Honeywell QR code scanning gun

2. Intelligent card reader or face recognizer

3. Waterproof automatic cutting label printer

4. Optional all-in-one computer and display

|

15050151202 Free service hotline |

|

Follow us Please scan the official account |

Copyright © HRC Automation(Suzhou)Co.,Ltd 备案号:苏ICP备19026496号